We’re here to help

Let us help you

AML Instruments supply a wide range of electromechanical and servo-hydraulic material tensile testing machines, varying in size and force capacities (1 kN – 6000 kN), with load cell options down to 1N. We also specialise in larger custom test rigs up to 5000 tonnes or more.

Product developers, quality control experts, and researchers in industries such as aerospace, construction, pharmaceuticals, and textiles need to know how a material behaves when it’s pulled on. That’s why they need accurate, reliable, and robust tensile testing machine systems.

Along with our expertly engineered European manufactured universal tensile testing machines from the likes of Barrus and GRIP Engineering, we can also design and build bespoke tensile test machines (a custom system) or customise standard models.

Not only can we supply you with a tensile testing machine, but more importantly, we can service, repair, and calibrate all material testing machines to ensure compliance, consistency, and reliability in your tensile test results. As standard, AML offer training and installation on every machine purchased.

Scroll further down the page to learn more about tensile testing and browse our selection of tensile testing equipment, including the space-saving Single Column Tensile Tester and high-end Barrus RED Twin Column Material Testing Machine.

Showing 1–12 of 20 results

Filter

Price on quotation

Find Out MoreA tensile test is the pulling apart of a material by a universal testing machine to see how it reacts. The pulling is continual until its permanent deformation (elastic limit) or until it breaks.

During the tensile test, data recording is continual from start to finish of the applying force. The following tensile properties are directly measured during a tensile test: tensile strength, max elongation or strain, and reduction in area.

Understanding the above mechanical properties can reveal modulus of elasticity, deformation, yield strength, and strain-hardening characteristics.

Tensile tests are important for quality control in the production of a wide range of products. This could be anything from assessing the tear resistance of fabrics to measuring packaging material strength or the durability of aircraft wings. This ensures the materials being used can withhold the required amount of stress and strain before they hit the market.

Without this test, some faulty materials may make it through to the final product, resulting in a poor user experience, injury, or in extreme cases fatality. Test specimens can be small or large — the most common types of materials that undergo tensile testing are composites, metals, plastics, rubbers, and textiles.

Designers require several essential datasets to ensure their product will be safe for its intended use. These tests are also imperative for quality control purposes by determining a material’s mechanical properties.

These include:

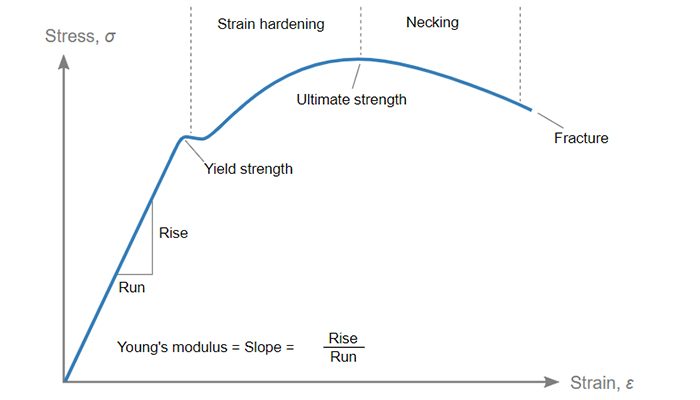

This law states the extension of a spring is proportional to the load applied, up to the elastic limit. Products are usually designed with a safety factor never to exceed this limit and break.

The modulus of elasticity measures the stiffness of raw materials. It determines how much the material will deform when applying force on a linear curve.

Hooke’s Law no longer applies when there is a deviation from the linear curve, as the material has some persistent deformation. Conversely, by removing the tensile load while in the initial linear region, the material will return to its exact condition before the tensile testing begins.

It’s important to know this value as it helps designers calculate how much stress their product can take without irreversible deformation.

Offset Yield Strength is the approximation of the materials elastic limit. This is useful for material that don’t display a clear change in behaviour from elastic to plastic, making it difficult to determine the yield strength. A parallel line is offset usually by 0.2% at the intersection of the line representing the yield point.

The strain or percent of elongation that occurs when a tensile test specimen breaks. This value can be used to calculate tensile strength, modulus of elasticity, yield strength, etc. Engineering strain and true strain are two additional ways of expressing strain measurements.

Yield strength is the maximum amount of force a material can take before it starts to deform permanently. Designers need this information as they should never design their products to go beyond this limit, as it makes them unsafe for their intended use.

In its simplest form, a tensile tester is a frame, motor, and load cell. The load cell is on a motorised arm and the load cell is connected to the material using a grip. The other end of the material is connected to the base of the tensile testing machine.

It works by applying a controlled and speed-appropriate load to the specimen until it breaks. As well as considering the material being tested, it’s vital you follow an ISO or ASTM standard to the speed set out in that specific tensile test standard.

The machine will measure the amount of force applied and the elongation of the specimen (until a break occurs), with the data then used to create a stress-strain curve which shows how much force and elongation is applied to the specimen.

Below is a list of the standard parts you’ll find with all tensile testing machines.

The priority of the drive system within a tensile test machine is to feed electricity into the motor at varying amounts to control the speed of the cross head.

Electronics control moving parts within the tensile testing machine. A microprocessor in the closed-loop servo controller allows the crosshead speed and consequently the load rate to be regulated.

An extensometer is used to precisely measure the elongation of the specimen. It’s often referred to as strain measurement. The sensor will be mounted in-line with the test specimen and will measure any movement that occurs.

A load cell measures the force applied to the test specimen. It converts tension force into an electrical signal which can be measured and calculated into the relevant force units.

A tensile testing machine will either be single or dual-frame, with the force capacity being the deciding factor. High-capacity frames can withstand greater force and feature a twin-column design.

The specimen is placed between the grips attached to a crosshead. The moving crosshead moves up and down along the column, pulling on the material under test at a constant speed.

The strain rate (elongation) in a test specimen is related to the crosshead speed.

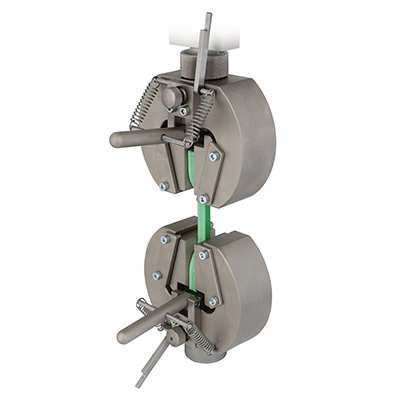

A tensile test specimen is clamped into the tensile grips and pulled until it breaks or deformation occurs. The load applied to the machine will be transferred through these gripping mechanisms, which should always return to their original state after a test has been performed.

Each machine could have several grips and fixtures, allowing the testing of different materials.

The test software (accessed through a computer) allows the controller to configure, run, and view the test results. The testing process can be viewed on a real-time dynamic display assisting the operator in maintaining uniformity and standard compliant test configurations.

After the tensile test, the data can be plotted on a graph to show the stress-strain curve.

A stress/strain curve shows the relationship between the engineering stress and engineering strain on a material.

This curve is important as it will help designers understand how their product behaves when force is applied to it.

Most tensile testing is carried out to meet standards published by The International Standards Organisation (ISO) or The American Society for Testing and Materials (ASTM).

Both organisations lay out the tensile properties, parameters, and common standards for various raw materials. There are tensile testing standards for exactly how the test should be performed, the test speeds, methods of calculation of the results, etc.

By ensuring material and products entering the supply chain have met the minimum requirements, end-users can expect the product not to fail if used as intended.

All our tensile test apparatus is specifically designed to meet your requirements based on testing capacity, types of material, applications, and industry standards such as ASTM E8 for determining the tensile properties of metallic materials.

From offering advice on choosing the correct machine and accessories to getting the most out of your tensile tester after purchase, we’ll help you optimise your tensile testing in no time.

☎️ 01522 789375

Let us help you