We’re here to help

Let us help you

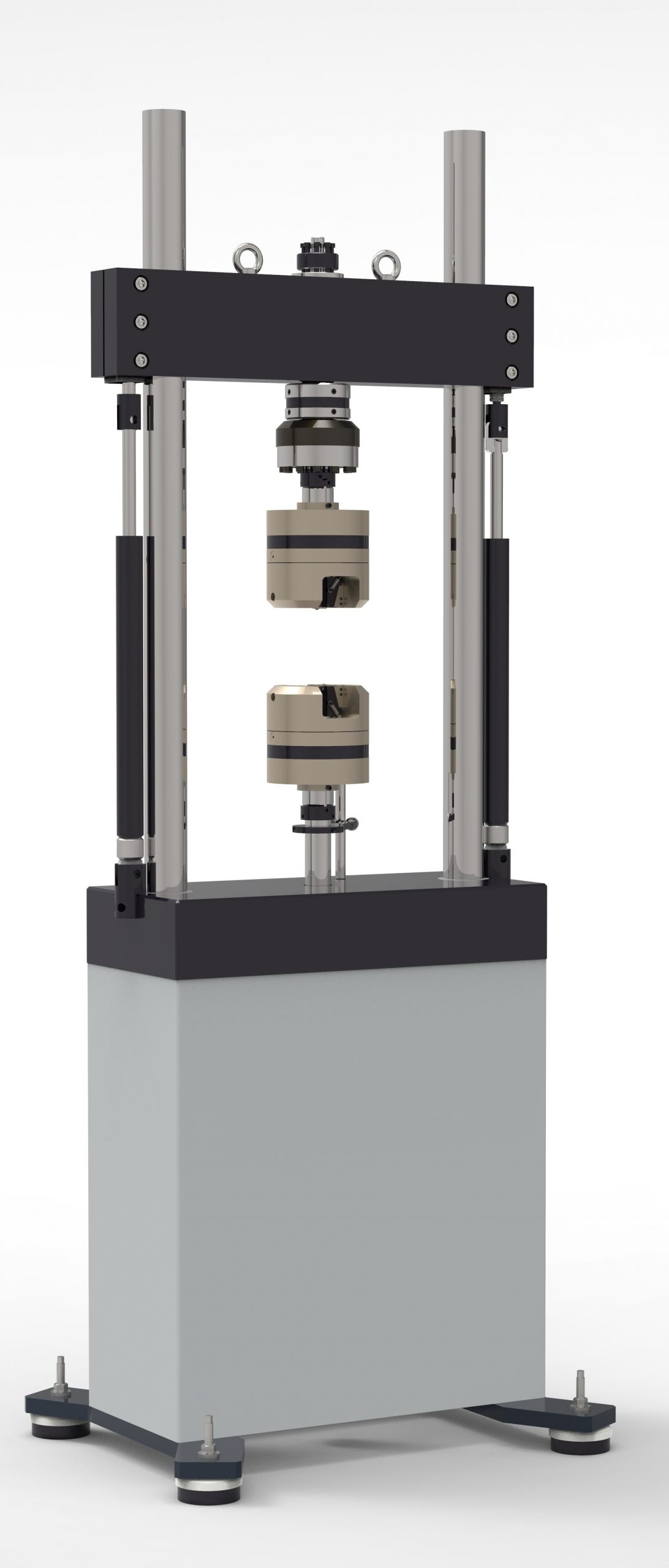

Servo-Hydraulic Dynamic Fatigue Test Machine BMT-D Series

Manufactured by Besmak

Dynamic Fatigue Test Machine BMT-D Series from Besmak in Turkey are industry leading Dynamic Fatigue Test Machines. These advanced material testing machines are ideally suited to a wide range of materials including, steel, composites, plastics, rubber and many more.

The Servo-Hydraulic Dynamic Fatigue Test Machine are the highly dependable workhorse of any materials testing laboratory. They can perform a wide range of low and high cycle fatigue, fracture toughness, crack propagation and other dynamic tests. Furthermore when equipped with the necessary grips and fixtures the machines can also be used for a wide range of static tests including tensile, compression, shear and bend thus making these a truly Universal Testing Machine.

Each Dynamic Fatigue Test Machine is equipped with a state of the art controller and servo control system the system is supplied advanced software ensuring ease of use.

Frame / load cell sizes from 25 kN to 5000 kN

We can customise standard Fatigue Test Machines or we can design and build bespoke testing machines to meet your exact needs.

Our Dynamic Fatigue Test Machines offer many great features at a competitive price. Backed up by AML’s famous post sales support, our engineers are on hand to ensure you get the most of your dynamic test machine and make sure it’s working exactly as it should.

The Servo-Hydraulic Dynamic Fatigue Test Machine BMT-D Series is controlled by the latest generation of EDC (Electronic Control Unit). This EDC is the world’s most sensitive dynamic control system and was first developed in 1975.

The ECD obtains the signals from the test frame, load cell and extensometer and ensures close control of the machines parameters. The controller accepts a wide range of inputs and when configured, accessories such as additional load cells or extensometers can be plugged in and are automatically recognised by the controller and software.

All Dynamic Fatigue Test Machines come equipped with powerful yet easy to use software. Ensuring real time collection of data and control of the machine. The software allows the configuration of all test types with easy customisation of the reports etc. to meet your exact needs.

Looking for calibration or service for your existing Dynamic Fatigue Test Machine, we can help. Contact us today!

Let us help you