We’re here to help

Let us help you

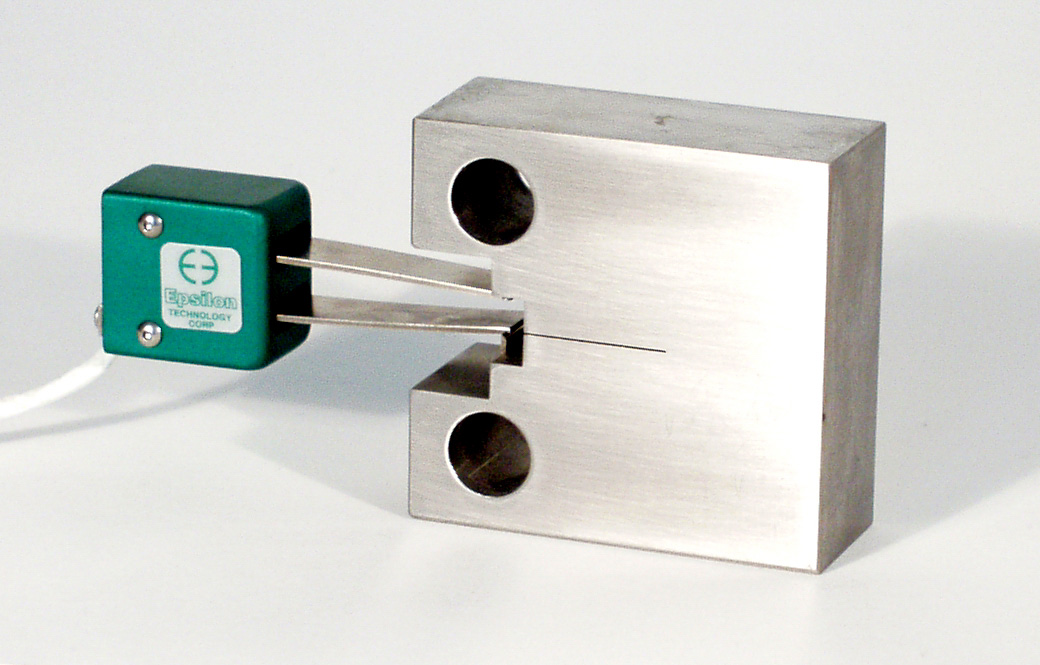

Fracture Mechanics Clip-On Gages – Model 3541

Manufactured by Epsilon Technology Corp

Fracture Mechanics Clip-On Gages – Model 3541. For fracture mechanics studies, these COD gages are in compliance with standardized test methods, such as ASTM E1820 for determination of fracture toughness properties of metallic materials.

The Model 3541 is designed for determination of fracture mechanics parameters such as JIC, KIC, R-curve, fatigue crack growth rate (da/dN), and testing to standards such as E1820, E399, E647, etc. These COD gages conform to the requirements of E1820 for JIC and R-curve determination. Special configurations are available to meet the requirements of ASTM E399 for fracture toughness (please consult the factory for these configurations). In addition, the modified groove design complies with E1820 tests where greater stability and accuracy results from the sharper groove root.

Clip-on gages are used for a variety of fracture mechanics tests, including compact tension, arc shaped, disk shaped, bend specimens or other specimen geometries in compliance with ASTM and other standards organization’s test methods. Clip-on gages can be used directly on test specimens where the knife edges are integral with the test specimen or, alternately, with optional bolt-on knife edges mounted on the test specimen.

Model 3541 crack opening displacement gages are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller with electronics for a strain channel, and Epsilon will equip the extensometer with a compatible connector that is wired to plug directly into the controller. For systems lacking the required electronics, Epsilon can provide a variety of signal conditioning solutions that enable connecting to data acquisition systems or other equipment.

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V, nominal, depending on model

Accuracy: All standard configurations meet ASTM E1820, ISO 12135, and ISO 9513 Class 1 requirements for accuracy. A test certificate is included. Models that additionally meet ASTM E399 accuracy requirements are available in 2.5 and 4.0 mm (0.10 and 0.15 inch) measuring ranges. A test certificate for ASTM E399 is included with those models.

Linearity: ≤0.2% of full scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to +210°F)

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

Operating Force: 9 to 14 N (2 to 3 lbs), depending on model

Let us help you