We’re here to help

Let us help you

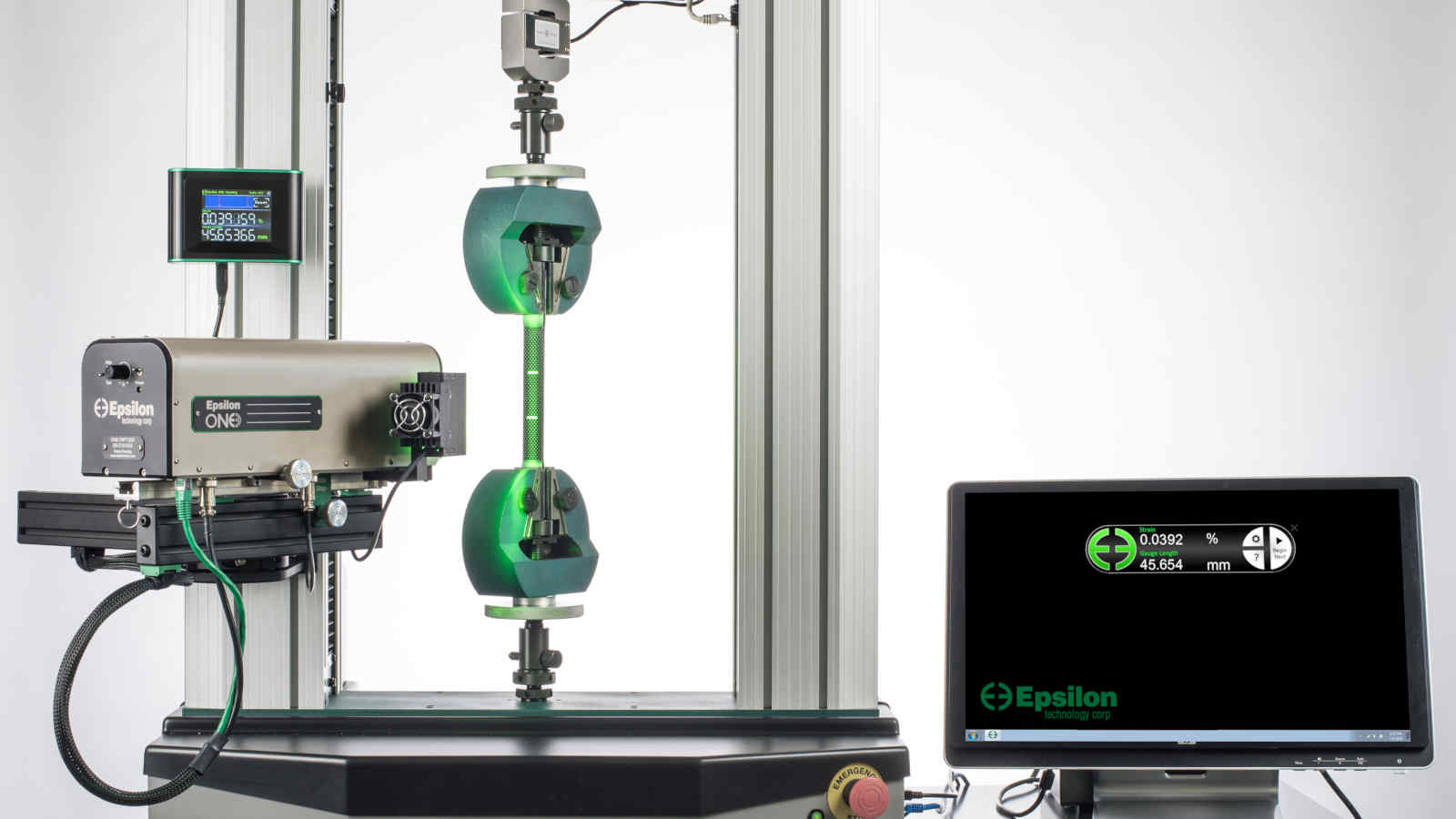

Precision Optical Extensometers – Epsilon ONE®

Manufactured by Epsilon Technology Corp

Precision Optical Extensometers – Epsilon ONE® Breakthrough Performance • Incredibly Easy to Use • Works With Any Test Machine

Epsilon ONE® high-precision optical extensometers measure axial strain with industry-leading resolution, accuracy, and speed. Innovative Instant Reset, Always On and Laser Alignment features maximize performance and increase testing throughput.

Epsilon ONE® optical non-contact extensometers perform high-accuracy, high-resolution, non-contacting axial strain and displacement measurement. These extensometers are suitable for testing high-modulus materials such as metals and composites, high-elongation materials, thin or delicate specimens, cyclic fatigue, strain controlled testing, deflectometer applications, and measuring crack opening displacements. Strain or extension is measured and output in real time.

Epsilon ONE’s high resolution and ISO 0,5 / ASTM B-1 accuracy classes make it suitable for non-contact measurement of a wide range of strain values, from very small strains required to measure modulus* of metals, composites, ceramics and CMCs through elastomers and everything in between.

Class-leading accuracy and resolution are achieved by Epsilon’s comprehensive optical path optimization, a unification of several optical technologies and signal processing algorithms. Ultra-high camera resolution, real-time data rates up to 3000 Hz, minimization of optical error sources, and signal processing techniques provide high strain resolution and accuracy with the lowest noise. No other system on the market combines all of these technologies.

The Laser-Assist Alignment System provides an instant alignment and distance spot check. Epsilon ONE will project pre-aligned laser lines on the specimen before the test, revealing any misalignment. During the test, high precision telecentric lenses on the PT models eliminate errors due to out-of-plane movements – a common source of errors for many video extensometers. Epsilon ONE arrives factory calibrated – there are no calibration grids or gauge length bars, saving a great deal of time.

The system sets up for new specimen types in minutes and requires very little training or skill to use. The desktop user interface software and optional Touch Interface provide continuous digital readouts and status information.

Epsilon ONE was designed for the fastest specimen cycle times. Auto-start repetitive tests without any software interaction; Epsilon ONE is always running, and its Instant Reset and Automatic Mark Detection eliminate software start/stop interactions common with video extensometers.

Epsilon ONE provides a calibrated ±10V strain signal as an input for the testing machine’s controller. The extensometer fits all types of materials testing machines, including machines that have an environmental chamber with a window (contact Epsilon for fitment).

*As with clip-on extensometers, accurate measurement of modulus requires a well-aligned load train and grips, and symmetrical specimens that are centered in the grips. Gauge lengths ≥25 mm are recommended in most cases. Contact Epsilon for additional Best Practices.

Key Applications

Field of View: 52-500 mm. See specific optics packages; contact Epsilon for other options.

Working Distance: 150-300 mm typical. See specific optics packages; contact Epsilon for other options.

Real-Time Data Rate: 300-3000 Hz, >2000 Hz typical. Includes image frame rate, analysis, analog output, and digital output

Analog Output: ±10VDC typical, short-protected. Selectable units & range. Includes 2.4 m (8 ft) shielded output cable with connector for test equipment.

Digital Output: 16-64 bit at >2000 Hz typical, over RS232. Includes 1.8 m (6 ft) shielded null modem cable.

Resolution: <0.5 µm quasistatic, <2.5 µm dynamic, <0.1 µm creep; Typical RMS resolution at typical settings. Resolution is a function of the optics and filter settings. See Guide for details.

Extensometer Class: ISO 9513 Class 0,5 and ASTM E83 Class B-1 or better typical at ≥10 mm gauge length

Absolute Accuracy:

PT models: <±1 µm or 0.5% of value, not exceeding ±30 µm typical

CE models: <±1 µm or 0.5% of value

Thermal Drift: Room Temperature Stability <0.002%ε/°C (20 µε/°C )

Minimum Specimen Size: < Ø20 μm (0.001”)

Gauge Length: 2 mm minimum, ≥4x specimen width or diameter recommended. For gauge lengths <10 mm contact Epsilon.

Maximum Elongation: >1000%, limited by field of view and gauge length

Maximum Tracking Speed: >1500 mm/second (90,000 mm/minute)

Cyclic Testing: >100 Hz typical cyclic test frequency, waveform independent

Strain Control: Suitable for monotonic and cyclic strain control applications

Out-of-Plane Sensitivity*: Allowable out-of-plane motion for ISO 9513 Class 0,5 @15 mm gauge length and ASTM E83 Class B-1:

<1000 µm (0.040”) for ONE-PT-xx

<25 µm (0.001”) for ONE-CE-xx

*Understand this specification before you purchase any optical extensometer – see this Tech Note

Power Supply: 100-240 VAC, 50-60 Hz, 100W, IEC 320 C14 receptacle. Specify plug type when ordering

System Environment: 10-40°C (50-100°F), for use and storage; 20-80% relative humidity non-condensing environments

Host PC (optional): Requires Windows 7 or 10 PC, 900×550 minimum display, one serial or USB port

Let us help you