We’re here to help

Let us help you

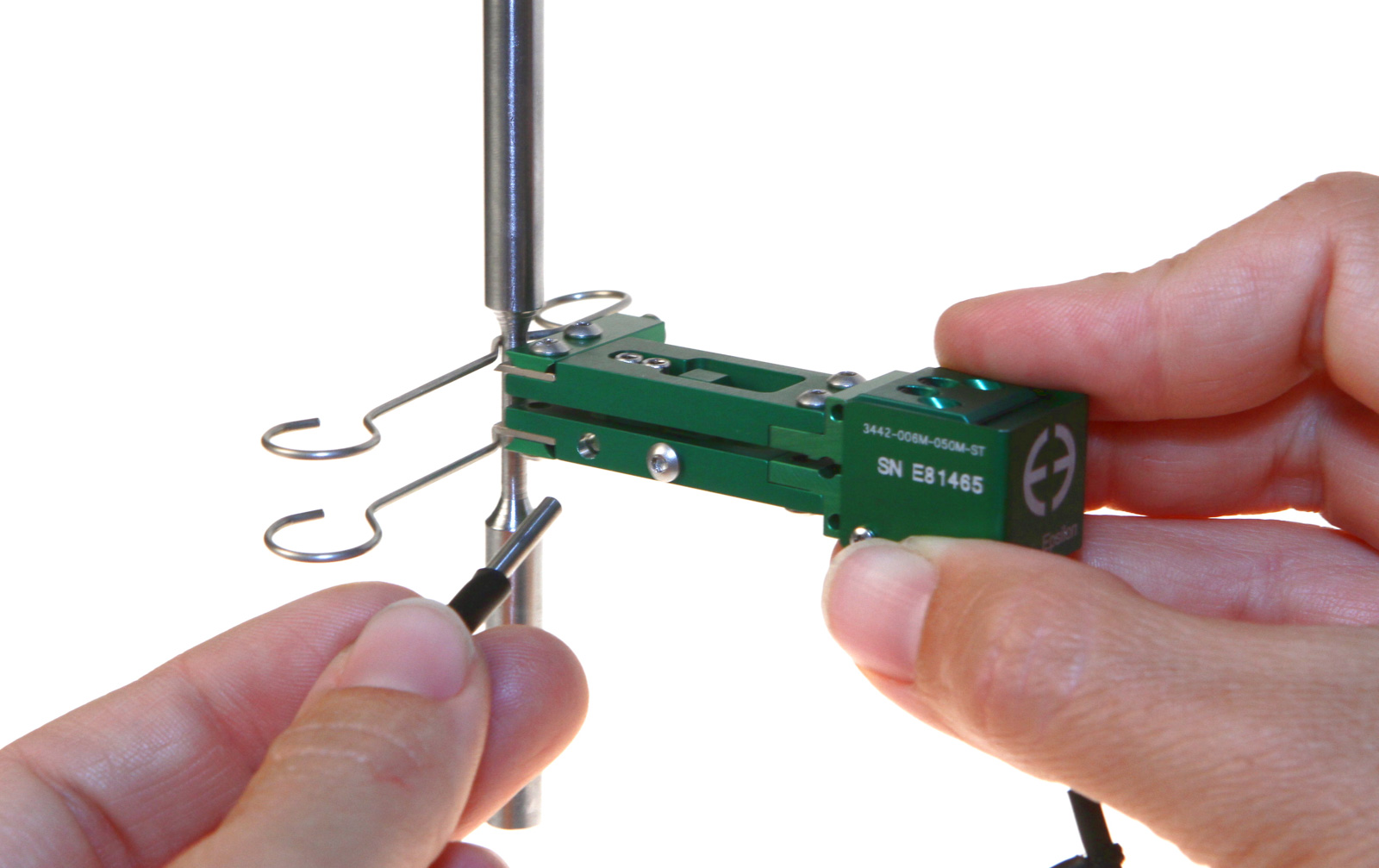

Miniature Axial Extensometers – Model 3442

Manufactured by Epsilon Technology Corp

Miniature Axial Extensometers. Small profile and ultra-light weight, these units are appropriate for testing small and delicate samples yet rugged enough for daily use on standard specimens. Ideal for strain measurement of wire specimens, sheet materials, and standard ASTM or ISO specimen geometries. Excellent for low and high cycle fatigue testing.

Weighing as little as 8 grams, these miniature extensometers are designed to have very low operating force with minimal specimen influence. All use an improved version of Epsilon’s dual flexure design which makes them very rugged for their size. With a compact module that is 15.2 mm (0.6 inches) high, they will fit in the limited space between grips that is typical with small test samples. Gauge lengths can be as short as 3 mm or as long as 50 mm. A newly designed gage setting pin and assembly allows the gauge length to be set accurately and repeatably to ASTM and ISO requirements for all gauge lengths. Reengineered quick attach wire forms provide simple and secure specimen attachment. Wire forms for round and flat specimens are included, as well as knife edges in flat, 3-point, and vee configurations. The wire forms may be removed to enable mounting using elastic bands or springs. A tethering attachment point provides fall protection and enables counterbalancing of the extensometer’s weight when testing delicate specimens.

Model 3442 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller with electronics for a strain channel, and Epsilon will equip the extensometer with a compatible connector wired to plug directly into the controller. For systems lacking the required electronics, Epsilon can provide a variety of solutions for signal conditioning and connection to data acquisition systems or other equipment.

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V nominal, depending on model

Accuracy: Standard configurations meet ASTM E83 class B-1 accuracy requirements for gauge lengths ≥6 mm and class B-2 for ≤5 mm. All standard configurations meet ISO 9513 class 0,5. A test certificate is included.

Linearity: ≤0.15% of full scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

Standard Quick Attach Kit: Fits round samples 0.5-13 mm (0.02-0.5 inch) diameter and flats 0.1-13 mm thick by up to 15 mm wide (0.005-0.5 inch by up to 0.6 inch); attach to larger specimens using rubber bands or springs (included)

Operating Force: Depends on model configuration; 10 to 100 g typical

Let us help you