We’re here to help

Let us help you

Tensile testing of materials is a crucial step in understanding how materials respond to tensile forces (the external load or pulling force applied). Let’s learn more about this destructive form of testing, and how it helps engineers and manufacturers ensure their products meet the required levels of ductility and strength.

A material tensile test (also sometimes called a tension or pull test) is one of the most basic and normally destructive tests you can perform on a material. The material is subjected to a controlled force in tension (pulling apart) until it breaks.

The results from a tensile test are used to help engineers and manufacturers select the correct material for a particular application or in quality control during the manufacturing process. While pulling on the material, you can find out how its strength is compared to how much it will elongate.

A tensile tester (also known as a universal testing machine) can also be used for performing compression tests as well. So rather than pulling something apart, you’re evaluating how materials such as cardboard and plastics behave under a compression or crush force.

Barrus universal testing machine with vertical grips and control panel, next to a computer displaying real-time stress-strain data for material testing.

Tensile testing and compression testing can be broken down into three main types: static, dynamic, and cyclic (fatigue). They’re all based on how the load is applied over time, revealing information about a material’s mechanical properties and gauging how it will perform under different types of loading conditions. Each test method serves a unique purpose and is explained in greater detail below.

This method is used to understand how a material behaves under a steady load over a period of time. By applying a constant compressive or tensile force that’s slow enough to allow the material to respond to the applied stress, you can determine the elastic modulus, Ultimate Tensile Strength (UTS), or yield strength of the material (see further down the page for definitions of these terms).

Loads are applied rapidly in dynamic materials tests. The notion here is the rate of dynamic loading is fast enough so the material doesn’t have enough time to “breathe”.

Determining its response under high strain rates is vital for impact, crash, and high-speed scenarios. Think about how about resilient buildings and structures need to be in high winds or the seismic force that materials used in car face in high-speed collisions.

In a cyclic (fatigue) tensile test, a repeated compressive or tensile force is applied to the material. This cyclic load varies between a minimum and maximum value, enabling you to measure the material’s fatigue lifespan (the number of load cycles it can withstand before failure). Industries such as aerospace, automotive, and healthcare regularly use fatigue testing and fatigue testing machines to test components like tyres, dental implants, etc.

However, Universal Testing Machines (UTMs) aren’t just restricted to compression or tensile tests. Other test methods typically available on these machines include:

A tensile testing machine will also measure the position of the arm where the load cell is fitted. This is utilised to calculate the strain or elongation of the material.

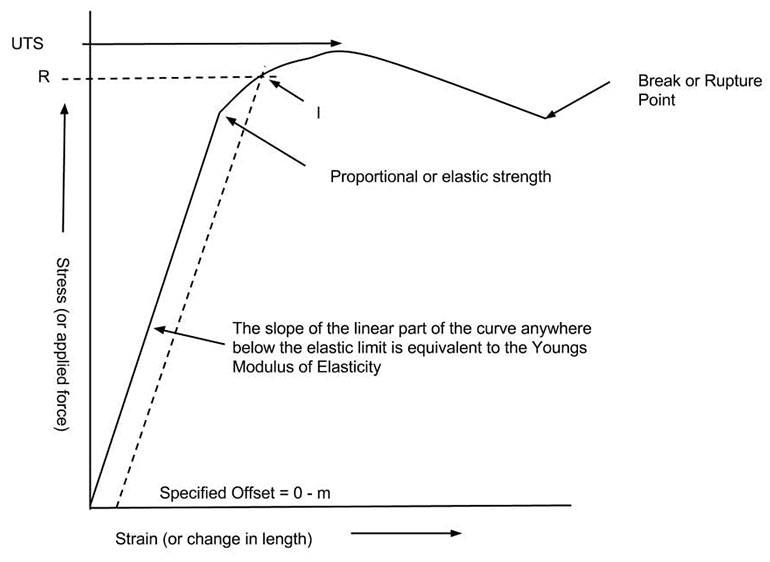

A huge amount of information can be acquired about a particular material or substance from tensile or compression testing. As you pull or push on the material until it breaks, you obtain a tensile or compressive profile. The resulting curve will show how the material has reacted to the forces being applied.

The point in which the sample fails is often of great interest, and is referred to as the breaking strength or the breaking force. The Ultimate Tensile Strength (UTS) is the maximum force measured during the test and is typically not at the point of failure.

All Universal Testing Machines supplied by AML Instruments come with software to analyse the results and perform complex calculations. Let’s begin by looking more closely at tensile test data and some of the typical tests and results it can throw up.

Most materials that are tested using a Tensile or Universal Testing Machine will begin by showing a linear relationship between the applied force (stress) and the elongation (strain) of the sample tested.

In this linear region of the test, the line obeys the relationship defined as “Hooke’s Law” where the ratio of stress to strain is a constant.

E is the slope of the line in this region, where stress (σ) is proportional to strain (ε).This is referred to as the modulus of elasticity or Young’s Modulus.

For some materials (e.g. certain plastics and metals), the yield point is not easily identified. An offset method is then used to calculate the yield strength.

BS A4 Part 1, BS EN 10002 and ASTM E8, provide a detailed method for metals, and ASTM D638 for plastics. The offset is specified as a percentage of the strain — this is usually 0.2% for metals and 2% for plastics.

The Stress “R” is determined from the intersection point “r” when the line of the elastic region is drawn from offset “m” becomes the yield strength by the offset method.

The tensile curves of certain materials don’t have a well-defined linear region. In this case there are alternative methods of determining the modulus of the material as well as the Young’s Modulus. These are the secant modulus and the tangent modulus.

Engineer operating a universal testing machine, preparing a specimen for mechanical testing.

The tensile strength of paper and board is critical to many converting and manufacturing processes, such as printers, carton manufactures, and tissue products. Stringent tolerances are set by customers of the paper mills to ensure the paper or board will run correctly through their machinery and produce a quality product for the end user.

The tensile strength of paper is usually expressed as kN/m and the machine is set to move the grips at a constant rate of elongation (speed). The sample which is a strip, normally has a width of between 15mm to 25mm.

Tensile index = tensile strength/grammage, quoted in Nm/g.

This is expressed in two main ways — engineering strain and true strain. Engineering (sometimes called Cauchy) strain is the most common expression of strain. It is expressed as a ratio of the total deformation of the initial dimension to the original length.

The True strain is similar but instead based on the instantaneous length of the specimen as the test progresses. Li is the instantaneous length and Lo is the initial length.

Another test often performed is the tensile energy absorbed. This is calculated from the area under the load / elongation curve — the units of the test are J/m²

Wet tensile tests for paper are performed in accordance with BS 2922/2, while puncher, dry, and wet tensile tests (Finch method) are often required for tissue products manufacturing.

These tests are performed to the requirements of British standards and International standards BS EN ISO 1925/4 and BS EN ISO 1925/5.

Ultimate Tensile Strength which is often shortened to tensile strength (TS) or ultimate strength is the maximum load a specimen sustains during a tensile strength test. This is not necessarily equated to the strength at the break of the specimen. Some materials are brittle, ductile, or may even exhibit both properties.

AML Instruments range of tensile testers can be configured and supplied with the correct fixtures and grips to enable them to perform a multitude of different tests and they can also test many different materials and substances.

This is the point in which a material stops deforming elastically and starts to deform plastically. This means when the load is removed it doesn’t return to its original condition.

Modulus of elasticity is a measure of stiffness, but only of the linear region of the curve. If the material specimen has the load applied within its linear region, it will return to its same shape and condition when the load is removed. At the point where the curve deviates from the straight line relationship and no longer shows linearity, Hooke’s Law no longer applies, resulting in some permanent dimensional deformation. This point is called the elastic or proportional limit.

From this point, the specimen reacts plastically to any increase in load or stress. The material will not return to its original, unstressed condition, size, or shape if the load is removed.

Let’s now take a look at the different types of compression and crush tests, and the characteristics they measure when a compressive or “crushing” load is applied to the material.

Crush and Compression Resistance Testing

Concora or corrugated crush testing is used to determine the edge profile compression strength of a fluted strip of corrugating paper. In a Laboratory, the Tappi T824 covers this method and the results are expressed in the units kN/m.

Edge compression testing is used to determine the load bearing strength of corrugated board to loads that act in parallel to the fluting. The BS EN ISO 3037 gives details of this method, with the results expressed in the units kN/m.

Flat crush testing is used to determine the load bearing strength of corrugate board to loads that act perpendicular to the fluting. The British Standard BS EN 23035 and International Standard ISO 3035 give details of this method. Results are expressed in the units kPa.

Ring crush testing is used to determine the compressive strength of paper and board. A round sample of material is inserted into an annular groove and then loaded until failure, with results expressed in the units kN/m.

Polymers play a vital part in everyone’s life in the 21st century, especially industries like automotive, electronics, and packaging. Tensile and compressive strength testing of plastics using ASTM, ISO, and other test methods helps assess their flexibility and strength.

There are many different tensile and compressive tests possible, and even more standards available from different standards institutes around the world. Some of the main standards used are listed below. Our team will of course help you select the best test and relevant standard for your testing needs.

Compression: ASTM D695, ASTM D1621, ASTM D3846, ISO 844, ISO 604, JIS K7092, JIS K7181.

Determination of the bearing strength of rigid plastics: ASTM E1012.

Dynamic / Fatigue: ASTM F1614.

Flexural: ISO 178, ASTM D790, ASTM D6272, JIS K7017, JIS K7171.

Peel, Tear, and Coefficient of Friction (CoF): ASTM D903, ASTM D1894, ISO 8067, BS ISO 8295, ISO 6383-1, ISO 11897, JIS K6854-2, JIS K7125, ISO 7886-1.

Shear: ASTM D3163, ISO 8067.

Tensile: ISO 527-, ISO 527-2, ASTM D638, ASTM D882, BS 2782:3 methods 326A-326C.

Tensile strength and elongation: BS 2782:3, ASTM D638, ASTM D882, ISO 527-1,2,3, ISO 1798, ISO 1926, JIS K7127, JIS K7161, JIS K7162.

The tensile properties of polymers (plastics) that are regularly measured are tensile strength, yield strength, % elongation, elastic modulus, and tensile energy absorbed.

Plastic bottle being tested using a compression testing machine.

There are a huge range of standards that cover the tensile and compressive tests of metallic (metals) such as castings, ropes and chains, sheet metals, steel plates, and welds.

Below is a table of the most common ones.

| Standard | Description |

| ISO 6892-1 | Metallic materials — Tensile testing — Part 1: Room temperature. |

| ISO 6892-2 | Tensile testing at elevated temperature |

| ASTM B598 | This standard covers the determination of the yield strength (0.01%, 0.02%, and 0.05% offset), at room temperature. It is intended for copper alloys in tempers commonly used for spring applications, and materials thicker than 0.010 in. (0.25 mm). |

| ASTM E209 | This standard covers the method, equipment, and specimens for compression tests on metallic materials. |

| ASTM E21 | This standard covers the method and equipment for the determination of tensile strength, yield strength, elongation, and reduction of area of metallic materials at elevated temperatures. |

| ASTM E238 | This standard covers the a pin-type bearing test of metallic materials to determine bearing yield strength and bearing strength. |

| ASTM E292 | This standard covers the determination of the time for rupture of notched specimens under conditions of constant load and temperature |

| ASTM E345 | This standard covers the tension testing of metallic foil at room temperature in thicknesses less than 0.006 in. (0.150 mm). |

| ASTM E8 | This standard covers the tension testing of metallic materials in any form at room temperature, in particular the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of area. |

| ASTM E9 | This standard covers the apparatus, specimens, and method for axial-load compression testing of metallic materials at room temperature. |

| BS 4A 4-1.2 | This standard covers the specification for test pieces and test methods for metallic materials. Tensile tests. Tensile tests - elevated temperature. Metric units |

| BS 4A 4-1.3 | This standard covers the specification for test pieces and test methods for metallic materials. Tensile tests. Uninterrupted creep and rupture tests. Metric units. |

| BS EN 10002-1 | This standard covers the tensile testing of metallic materials. Method of test at ambient temperature. |

| BS EN 10002-5 | This standard covers the tensile testing of metallic materials. Method of test at elevated temperatures. |

| BS EN 10319-1 | This standard covers metallic materials. Tensile stress relaxation testing. method for testing machines. |

| BS EN 13523-7 | This standard covers coil coated metals. Test methods. Resistance to cracking on bending (T-bend test). |

| BS EN 23312, ISO 3312 | This standard covers sintered metal materials and hard metals. Determination of Young's modulus. |

| BS EN 23327, ISO 3327 | This standard covers hard metals. Determination of transverse rupture strength. |

| BS EN ISO 7438 | This standard covers metallic materials. Bend test. |

| BS EN ISO 7500-1 | This standard covers metallic materials. Verification of static uniaxial testing machines. Tension/compression testing machines. Verification and calibration of the force-measuring system |

| BS EN ISO 7622-2 | This standard covers steel cord conveyor belts. Longitudinal traction test. Measurement of tensile strength. |

| BS EN ISO 8491 | This standard covers metallic materials. Tube (in full section). Bend test. |

| BS EN ISO 8496 | This standard covers metallic materials. Tube. Ring tensile test. |

| EN ISO 7438 | This standard covers metallic materials. Bend test. |

| ISO 10113 | This standard covers metallic materials. Sheet and strip. Determination of plastic strain ratio. |

| ISO 10447 | This standard covers resistance welding. Peel and chisel testing of resistance spot and projection welds. |

| ISO 1099 | This standard covers metallic materials. Fatigue testing. Axial force controlled method. |

| ISO 3327 | This standard covers hard metals. Determination of transverse rupture strength. |

Tensile testing machine gripping a metal specimen, which is partially fractured under tension, with black clamps and a cardboard background.

AML Instruments supply a huge range of tensile testers and compression testers. They are effective for testing various tensile test materials like aluminium, composites, paper, plastics, and even the tensile strength of adhesive tape. We also have over 3000 grips and fixtures, giving you the capabilities to perform just about any test imaginable.

While you’re here, don’t forget to keep your tensile testers ticking along nicely with our compression and tensile tester calibration services. Available on-site or at our state-of-the-art laboratory for your convenience, we’re here to help your business produce reliable test results for your designers, producers, or clients.

For all things tensile testing, get in touch today!

Let us help you