Benefits

- Increased throughput — non-contact design enables faster testing, especially in non-ambient conditions. This means no time is lost attaching or removing clip-ons, meaning more specimens tested in less time, as well as reducing the impact of operator influence on measurement outcomes.

- Unparalleled accuracy — meets or exceeds ISO 9513 Class 0.5 and ASTM E83 Class B-1.

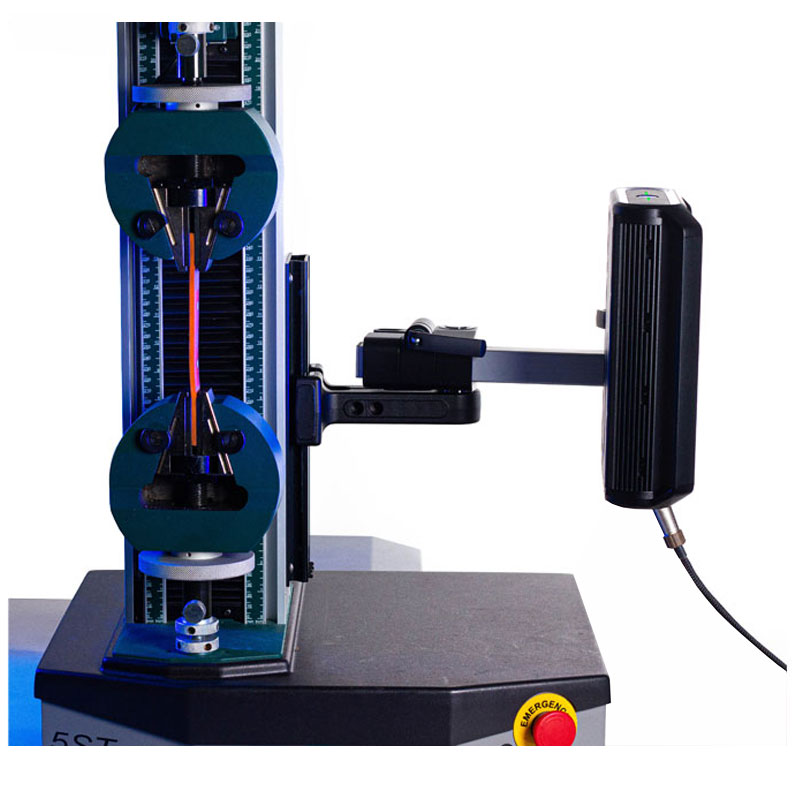

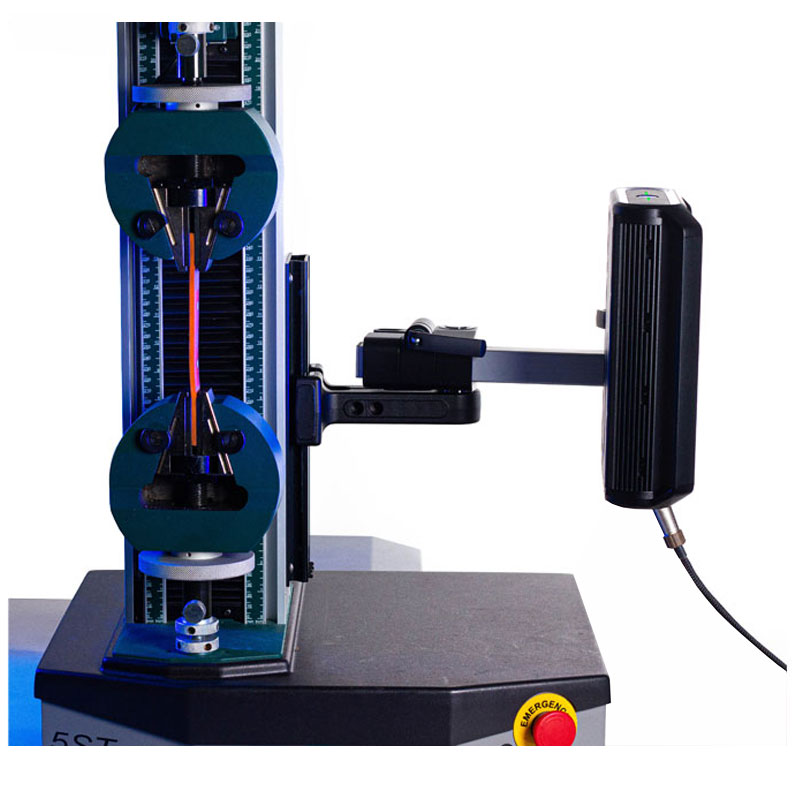

- Operating distance of 250mm to 350mm enables the U200 to accommodate different specimens and test types.

- Cost-effective — available at a comparable price to a Clip-on to reduce testing costs and drive faster ROI.

- Reduces test throughput times and complexity.

- Only requires simple specimen marking consisting of either filled circles, rings, or speckle pattern.

- Operates in harsh environments, challenging light conditions, and temperature chambers with no loss of functionality.

- Tests highly fragile specimens without impacting them.

- Avoids introducing stress concentrations, such as damage from knife-edge contact.

- Lower cost of ownership — With class-leading performance right out of the box, Vector eliminates the need for specialist high-temperature clip-ons and reduces maintenance overhead, resulting in fewer parts, fewer failures, and lower costs.

- Superior data quality — Simply point Vector at a properly marked specimen to capture accurate, consistent results. Operator variability is eliminated, ensuring reliable data every time.

- Intuitive design — get up and running with four easy steps: Install, Mark, Align, and Measure.

- Laser alignment guides, status indicator lights, and a flexible operating distance all assist the operator during setup and use.

- Easy to understand feedback from both the Vector software interface and Vector itself provides immediate confirmation of the state of the module.

- Extension and strain ranges are specified, providing clear guidance on performance for supported gauge lengths and allowing for easier 1:1 comparison with clip-ons. This makes it easier for users, particularly those familiar with clip-on extensometer spec sheets, to quickly determine whether a specific Vector configuration meets their testing requirements.

- Recommended operational temperature range of -100°C to +370°C. This is ideal for use in environmental chambers. We can also provide guidance that often enables accurate results at temperatures far exceeding 370°C.

- Extensometer calibration service available.

Measurement applications

Uniaxial, tensile, compressive, or flexural.

Vector Quick Start Guide

The following guide explains the basics to achieve extensometry measurement: Vector-Quick-Start-Guide