Benefits

- Excels in biaxial testing, offering important insights into material properties. This capability is crucial for Plastic Strain Ratio (r), Strain Hardening Exponent (n), and Poisson’s ratio testing as it reveals how the material behaves under various load conditions and provides comprehensive data.

- Increases strain test efficiency and reliability by reducing handling operations.

- Multiple variable gauge length measurement — axial from 7.5-70mm gauge length, transverse from 6.0-25mm gauge length.

- Enhanced resolution allows the B80 to also perform uniaxial testing of smaller specimens than the U200 and U70.

- Offers a 150Hz measurement rate, making it suitable for strain rate-controlled applications.

- Increased throughput — non-contact design enables faster testing, especially in non-ambient conditions. This means no time is lost attaching or removing clip-ons, meaning more specimens tested in less time.

- Reduces throughput times and complexity, automating the process of capturing strain and elevating data consistency and operator safety.

- Utilises a range of automation features such as specimen and gauge length detection to simplify the operator interaction and improve test reliability.

- Operates in harsh environments, challenging light conditions, and temperature chambers with no loss of functionality.

- Tests highly fragile specimens without impacting them.

- Avoid introducing stress concentrations, such as damage from knife-edge contact.

- Lower cost of ownership — With class-leading performance right out of the box, Vector eliminates the need for specialist high-temperature clip-ons and reduces maintenance overhead, resulting in fewer parts, fewer failures, and lower costs.

- Superior data quality — Simply point Vector at a properly marked specimen to capture accurate, consistent results. Operator variability is eliminated, ensuring reliable data every time.

- Measures to failure and performs strain-rate controlled testing compliant to ISO 6892 and ASTM E8.

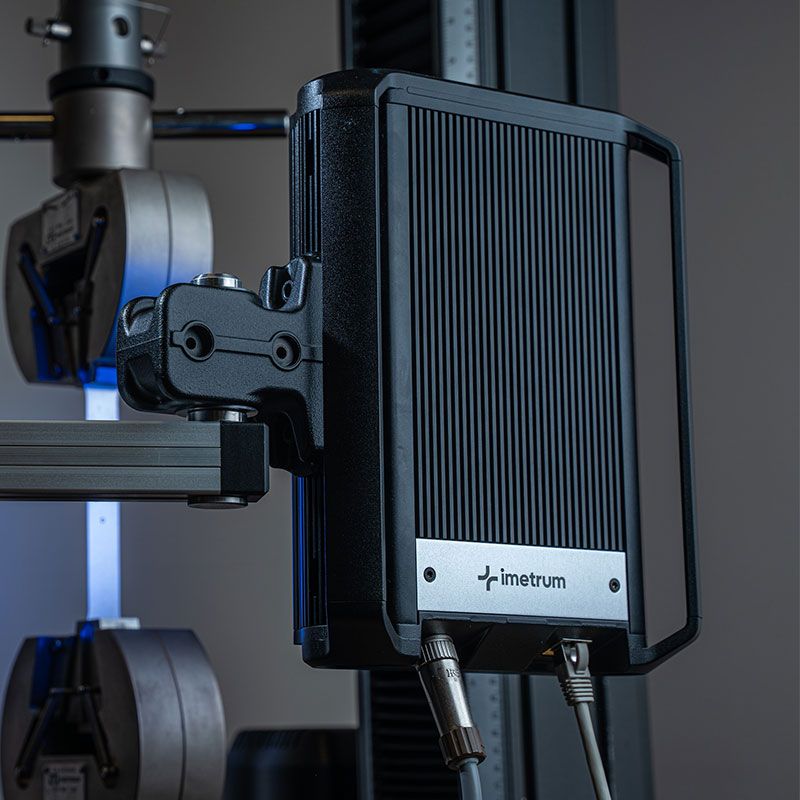

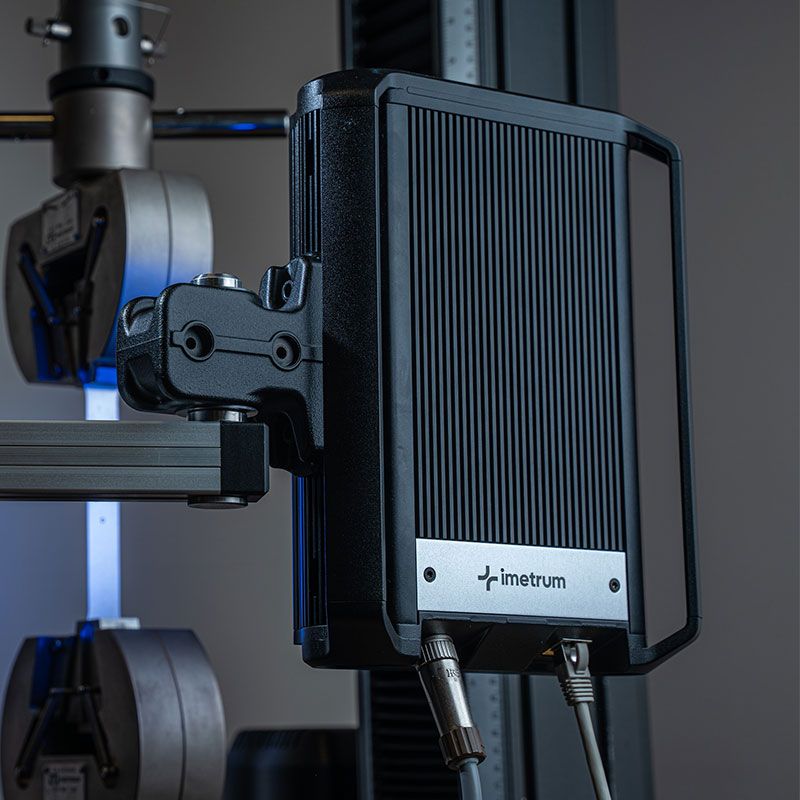

- Intuitive design — get up and running in four easy steps: Install, Mark, Align, and Measure.

- Laser alignment guides, status indicator lights, and a flexible operating distance all assist the operator during setup and use.

- Easy to understand feedback from both the Vector software interface and Vector itself provides immediate confirmation of the state of the module.

- Extension and strain ranges are specified, providing clear guidance on performance for supported gauge lengths and allowing for easier 1:1 comparison with clip-ons. This makes it easier for users, particularly those familiar with clip-on extensometer spec sheets, to quickly determine whether a specific Vector configuration meets their testing requirements.

- Recommended operational temperature range of -100°C to +370°C. This is ideal for use in environmental chambers. We can also provide guidance that often enables accurate results at temperatures far exceeding 370°C.

- Extensometer calibration service available.

Measurement applications

Uniaxial; Tensile, Compressive or Flexural.

Biaxial; Axial with central transverse.

Vector Quick Start Guide

The following guide explains the basics to achieve extensometry measurement: Vector-Quick-Start-Guide