We’re here to help

Let us help you

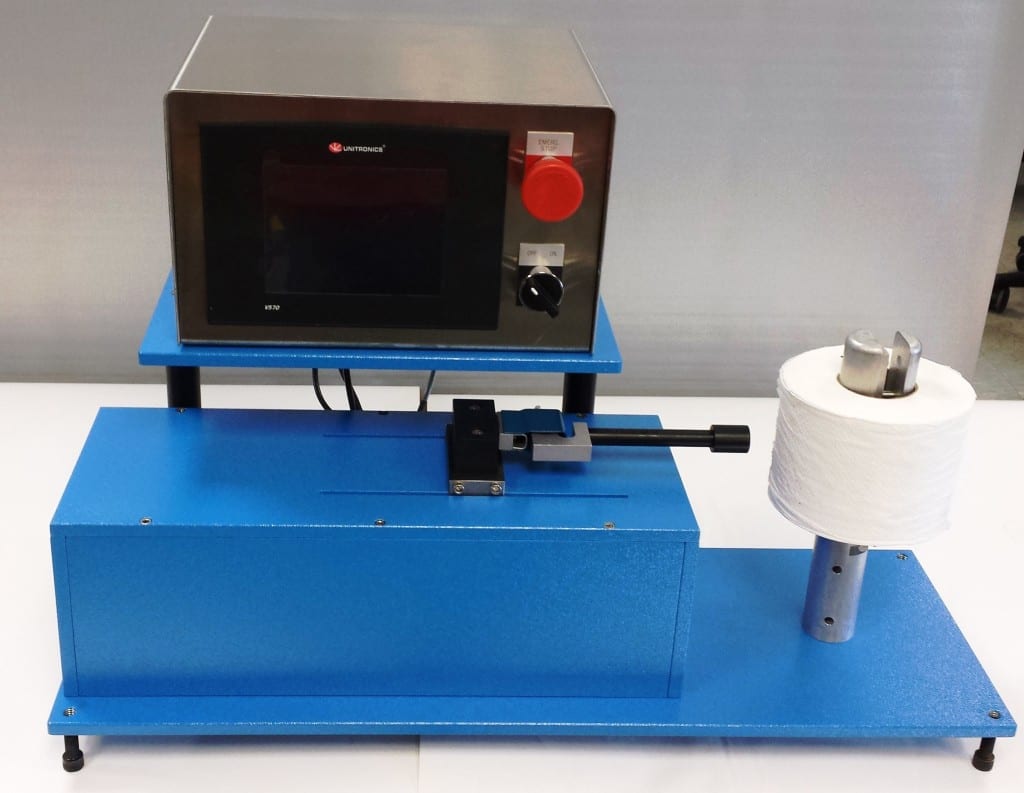

RDT – Roll Density Tester Kershaw

Manufactured by Kershaw Instrumentation LLC

The Roll Density Tester is an advanced, fully automatic tester for the Tissue Industry

This instrument is designed to measure the firmness of either toilet paper or paper towel rolls. This is the newest generation of this tester and includes the following features.

The load cell assembly is mounted on a moving sled. When the test begins the sled will move toward the sample roll to compress the roll and complete the test. Once the load cell probe contacts the roll the displacement circuit begins to measure the penetration of the probe as it continues to move. Once the probe reaches a preset force ( usually the standard force of 650g) the displacement circuit records this “Firmness” or penetration value and returns the sled to the home position. The firmness number is locked on the digital display until the beginning of the next test.

All of the control functions of this roll density tester are provided on a 5.7 inch touch screen PLC. All of the push buttons, digital readouts, calibration routines, and complete operating instructions are programmed into this touch screen PLC.

This newest version of the Roll Density Tester, Model RDT – 16 allows the operator to mount the instrument in either the horizontal or vertical position.

With the legs installed on the instrument it can be set horizontally onto a bench top as shown in the attached drawing. If a bench is not available or the instrument is to be used on the production floor where space is limited the instrument can be mounted vertical by removing the 4 legs and fastening the instrument to a vertical surface using the four mounting holes as shown in the attached drawing.

The touch screen PLC control panel has a universal mount that allows it to be mounted either horizontally or vertically.

This newer version allows for larger diameter sample rolls. The RDT – 16 will accommodate 3″ – 10″ diameter rolls. In addition, this newest instrument does not require the operator to mechanically adjust the spindle when changing roll diameters. The roll diameter is simply entered into the PLC via a virtual keypad and the instrument will automatically accommodate for the diameter of the sample roll.

New adjustable spindle there is no need to change spindle to accommodate different core sizes. The new spindle design is adjustable

AML Instruments our proud to be the European Agents for Kershaw Instrumentation and fully support their range of instruments.

Retro Fitting Service For Old Generation Roll Density Testers

We can fit the new touch screen PLC controller to all old generation instruments.

Calibration service available please ask for a price.

All specifications, illustrations and descriptions of products are intended to give a general idea of the products available and are subject to alteration. We reserve the right to substitute an alternative of similar specification at our discretion. We have taken all reasonable steps to ensure the accuracy of product information provided, but we accept no liability for any errors or omissions.

All specifications, illustrations and descriptions of products are intended to give a general idea of the products available and are subject to alteration. We reserve the right to substitute an alternative of similar specification at our discretion. We have taken all reasonable steps to ensure the accuracy of product information provided, but we accept no liability for any errors or omissions.

Let us help you