We’re here to help

Let us help you

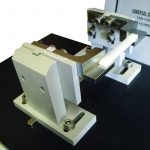

Ray-Ran Advanced Pendulum Impact Tester

Manufactured by Ray Ran

Suitable for testing Izod, Charpy, or Tension impact, this Pendulum Impact Tester utilises advanced microprocessor technology to determine the energy required to break or rupture specimens such as ceramics, composites, nonferrous metals, and plastics.

Built with operator simplicity and versatility in mind, it delivers high accuracy for product development and quality control applications.

Impact velocities are variable from 1.5 m/s up to 3.8 m/s and combined with highly accurate variable weight hammers which are electronically released by a solenoid, enabling impact energy ranges up to 50 Joules to be reached.

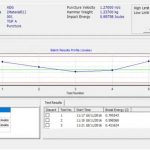

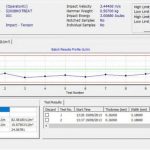

At the start of each batch of tests, a simple calibration of the apparatus is conducted for bearing resistance and windage. After each test sample has been tested, the results are displayed on the easy-to-read LCD, giving the Impact energy in KJ/M and KJ/M².

Notched or Un-notched specimens can be tested using the Izod method. Complies with International Test Standards ASTM D256, ASTM D4812, and ISO 180. Impact hammer energies are available from 0.5 J up to 25 J

Complies with International Test Standards ISO 179, ASTM D256, ASTM D6110, DIN 53453, DIN 53753, and BS 7413. Impact hammer energies are available from 0.5 J up to 50 J

Complies to International Test Standard ISO 8256 Method A. Impact hammer energies are available from 0.5 J up to 50 J.

Sample diameters up to 25 mm can be tested with hammer energies of 7.5 – 15 J. The test specimen is supported as a horizontal beam similar to Charpy test conditions and complies with International Test Standards ISO 7628 and ISO 9854.

The component test examines the influences of both the design and the manufacturing processes of a component by measuring the impact energy in Joules, required to break a complete or part of a section of a finished component. If a component has a critical cross-sectional area that needs to be tested, then by entering this area into the microprocessor the energy in KJ/M² can be obtained. The apparatus is supplied as standard with Ray-Ran’s Techni-Test Windows-based PC software. Test results can be printed directly from the Techni-Test software or can be saved and exported. CSV files which can be opened with Microsoft Excel.

Applications: Impact testing, sample testing, strength testing.

Materials: Aluminium, composites.

ASTM D256, ASTM D4812, ASTM D6110, ISO 13802, ISO 179, ISO 180, ISO 7628, ISO 8256, ISO 9854

Weight: 110kg

Dimensions: 630 x 500 x 760 mm (WxDxH)

Power: 110-240VAC, 50-60hz

Display: 160 x 128 dots graphic LCD module with alphanumeric keypad

Let us help you