It’s that time again. GRIP Engineering have released their first (and latest) newsletter of 2026 presenting a selection of their newest test fixtures for universal testing machines. We’ve highlighted their newest selection of test fixtures in more detail below (datasheets are available on request).

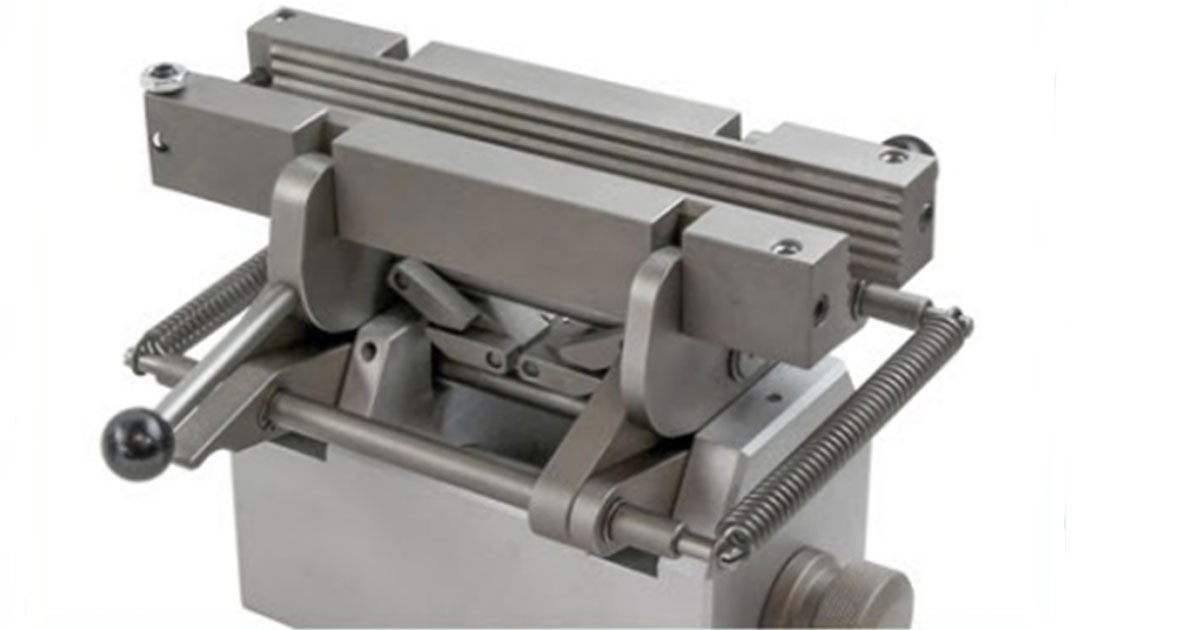

TH11-20-W200-Af60+BW30x200

The special scissor-type grip with extra-wide, wave-shaped jaws has been specifically developed for the reliable testing of nonwoven materials, ensuring optimal force distribution, secure specimen holding, and highly reproducible test results.

Max. load: 20 kN

Jaw width: 200 mm

Clamping surface: 30×200 mm

Steel: Nickel-plated

Coupling: Af60

Full perspective of the scissor-type grip testing apparatus mounted on a base.

Full perspective of the scissor-type grip testing apparatus mounted on a base.

Close-up view of specialised scissor-type grip mechanism designed for materials testing.

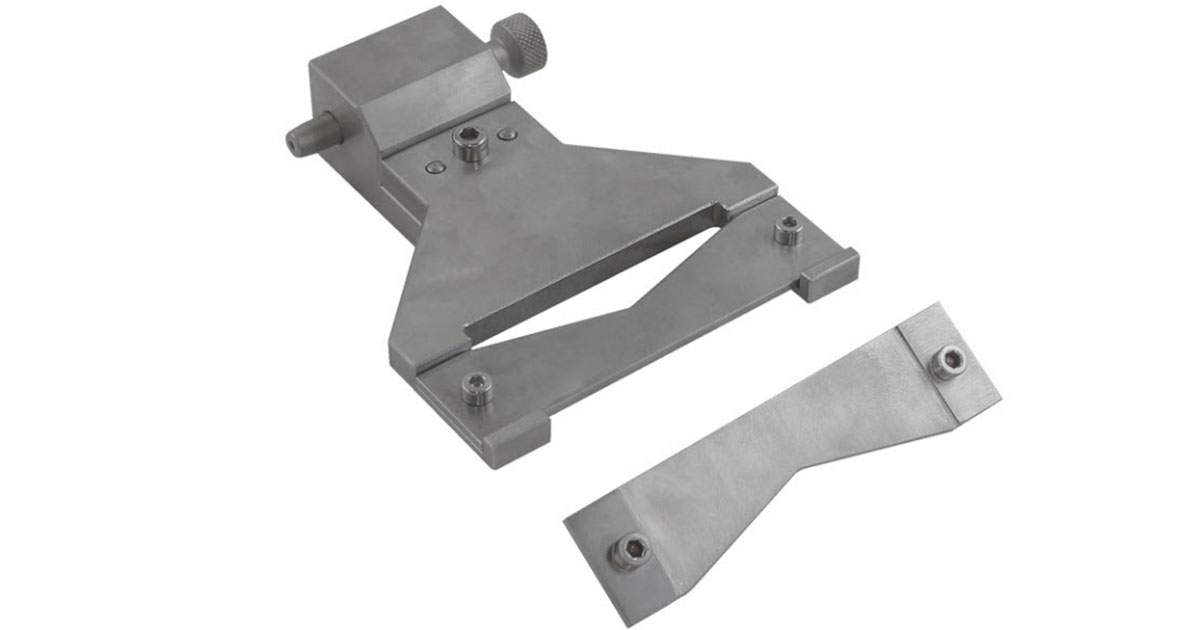

THS981-70-Af159

Special holder for reliable edge tearing strength testing of paper, designed in accordance with TAPPI T470. It’s made from stainless steel and ensures stable specimen positioning and reproducible results. An upper grip is required for testing.

Coupling: Af159

Specialised mechanical holder for edge tear strength testing.

Two hands tearing a sheet of paper from the edge.

THS1895

Special fixture designed to verify the fundamental performance requirements of uncut finished spectacle lenses in accordance with ISO 14889, ensuring reliable testing conditions and reproducible results.

Max. load: 100 N

Steel: Nickel coated

Coupling: Af159

Precision-engineered fixture specifically developed for testing uncut finished spectacle lenses.

Precision-engineered fixture specifically developed for testing uncut finished spectacle lenses.

Hands holding a curved spectacle lens, representing the type of uncut lens tested using a specialised performance verification fixture.

AML Instruments offers an extensive range of tensile tester accessories, including extensometers, environmental chambers, and special grips and fixtures. We also have the ability to design bespoke fixtures.

Find yours today by contacting a member of the AML team or visiting our site.