We’re here to help

Let us help you

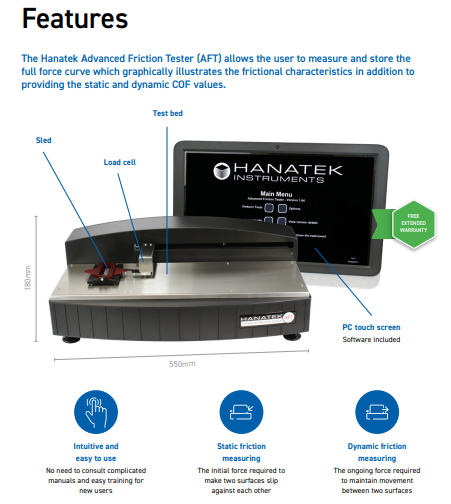

Hanatek Advanced Coefficient of Friction Tester (AFT)

Manufactured by Rhopoint Instruments

The Hanatek Advanced Coefficient of Friction Tester (AFT) is a comprehensive instrument for measuring coefficient of friction of printed cartons, plastic films, paper or packaging substrates.

The friction tester can be also used to measure the frictional properties of any flat surface including textiles, coated metals, plastics and leather.

As well as displaying the dynamic and static friction values for the material, the instrument also allows for the frictional profiles to be stored and referenced against new tests. This industry leading feature greatly assists in relating the feed and running speeds to a products surface coefficient of friction.

Optional extras are available to measure peel strength, blocking of films / coated cartons and tear strength.

The Hanatek Advanced Coefficient of Friction Tester (AFT) measures static and dynamic coefficients of friction

is the initial force required to make two surfaces move interdependently of each other.

The force required to maintain the movement between two pieces of material

A sample typically 63.5mm² with a known mass typically 200 grams, acting over the test sample is run across another sample at a pre determined speed.

Normally this is a face to face test, however a test against another material such as aluminium is sometimes done.

The test parameters are specified in ASTM D2534, ASTM D1894, ISO 8295, ISO 15359, and TAPPI T549.

The Hanatek Advanced Coefficient of Friction Tester (AFT) uses an intuitive touchscreen making it easily accessible.

Research and Development tool or Quality Assurance instrument

This flexible instrument can be configured for quality or research use.

Measure the forces required to close filled cartons.

This test ensures that carton based packages can be stacked and displayed correctly. Cartons must also be properly closed to ensure that any secondary process such as film wrapping can be performed.

During storage, films, labels or cartons can inadvertently block together making them difficult to separate and feed into finishing or packing lines.

Optional attachments transform the AFT into a precision peel test instrument, accurately measuring the force required to separate glued or laminated films, tapes, labels etc.

Optional tear strength attachment allows the user to measure and control tear strength to international standards.

Additional attachment to remove uncertainty in measurement of paper and board.

Detachable heated bed can be added to test frictional characteristics at elevated temperatures up to 110º C.

Want to know more about friction and slip testing see our guide Friction / Slip Testing Why & How To Measure Coefficient of Friction

Standards:

ISO 8295 Plastics – Film and sheeting – Determination of the coefficients of friction

ISO 15359 Paper and board – Determination of the static and kinetic coefficients of friction – horizontal plane method

ASTM D1894 Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

TAPPI 549 Coefficients of static and kinetic friction of uncoated writing and printing paper by use of the horizontal plane method

ASTM D2534 Standard Test Method for coefficient of kinetic friction for wax coatings

ASTM D3330 Standard Test Method for peel adhesion of pressure sensitive tape

FTM1FINAT Test Method no. 1, Peel adhesion (180°) at 300mm per minute

FTM2FINAT Test Method no. 2, Peel adhesion (90°) at 300mm per minute

FTM3FINAT Test Method no. 3, Low speed release force

FTM21FINAT Test Method no. 21, Ink Adhesion – basic

ISO 6383 Determination of tear resistance — Part 1: Trouser tear method

Let us help you