We’re here to help

Let us help you

Adhesives are one of the most widely tested products, meaning there are hundreds of different tests and test methods. This is also the same for adhesive and tapes testing.

Adhesives are critical to just about every part of our lives and are used in so many industries and products such as electronics, engineering, packaging, and woodworking. As such, understanding the adhesive qualities and limiting factors are integral to ensuring consistent quality.

Each of these adhesives or tapes will have been peel tested in both the development stage and as part of the manufacturing process. While there are many types and subtypes of peel test, what’s unique is most can be tested with just a single universal testing machine.

Let’s discuss half a dozen of the most common peel test types and how critical they are to performing the correct peel test for your material and/or application.

Peel testing (also called adhesion testing) is a fundamental mechanical test that measures the peel separation strength between two materials. The bonded materials are peeled apart at a defined angle and speed, enabling the manufacturer to determine how effective an adhesive will be when joining certain types of materials.

A peel test can be broken down into six main versions of peel strength tests, which we’ve covered in detail below.

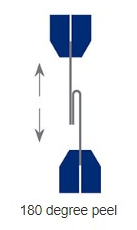

The 180-degree peel adhesion test is best suited to a flexible material that is bonded to a rigid substrate. A tensile tester and grips or special fixture are used along with a test panel to apply a force at 180 degrees to the panel.

Diagram of a 180-degree peel test setup.

Diagram of a 180-degree peel test setup.

The image below shows a special fixture for holding the test panel — this type of fixture makes the test easier to complete and more reproducible.

Metallic fixture or holder used in materials testing, typically for a peel or adhesion test.

Metallic fixture or holder used in materials testing, typically for a peel or adhesion test.

The test panels are generally float glass or stainless steel. The specifications of the test panels, test speed, and method of specimen preparation are specified in the relevant standard and test method followed.

180-degree peel tests are also widely performed in heat-sealed applications such as packaging — this differs as it doesn’t use a test panel and is generally called a T peel test (see later in this guide).

180 Degree Peel Test Methods and Standards

ASTM-D3330 - A – Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

ASTM-F88 – Standard Test Method for Seal Strength of Flexible Barrier Materials

ASTM-D3330 - B - E – Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

ASTM-D903 – Standard Test Method for Peel or Stripping Strength of Adhesive Bonds

ASTM-D5458 – Standard Test Method for Peel Cling of Stretch Wrap Film

ISO-8510-2 – Adhesives - Peel test for a flexible-bonded-to-rigid test specimen assembly - Part 2: 180-degree peel

ISO-11607-1 – Packaging for terminally sterilized medical devices - Part 1: Requirements for materials, sterile barrier systems and packaging systems

BS EN-1939 – Self-adhesive tapes. Determination of peel adhesion properties

BS EN ISO-8510-2 – Adhesives. Peel test for a flexible-bonded-to-rigid test specimen assembly. 180-degree peel

FINAT is the European association for the self-adhesive label industry. It also covers adjacent narrow-web product decoration and identification technologies.

FINAT-FTM1 – Peel adhesion (180°) at 300 mm per minute

FINAT-FTM3 – Low-speed release force

Afera is the European Adhesive Tape Association.

Afera-5001 – Self Adhesive Tapes - Measurement of Peel Adhesion from Stainless Steel or from its own Backing

The Pressure Sensitive Tape Council (PSTC) is the North American trade association for the pressure-sensitive tape industry.

PSTC-101 – International Standard for Peel Adhesion of Pressure Sensitive Tape

PSTC-4 – Relative performance of release coatings

PSTC-8 – unwind force of pressure-sensitive tape

TLMI is a trade association for the adhesive labels industry.

TLMI-L-IA1 – 180° peel adhesion - face stock

TLMI-L-IA2 – 180° peel adhesion - release liner

SAE-J 1907 – Peel Adhesion Test for Glass to Elastomeric Material for automotive glass Encapsulation

A tensile tester, grips and special fixture are used along with a test panel or part under test, applying a force at 90 degrees to the panel or part being tested. The 90-degree peel adhesion test is suitable for a flexible material that is bonded to a rigid substrate.

Diagram of a 90-degree peel test setup.

Diagram of a 90-degree peel test setup.

Mechanical 90-degree peel test apparatus used for measuring adhesive strength between two bonded materials.

Depending on the shape or size of the specimen or test panel these peel tables can be configured in many different ways. For information on the correct configuration and details on the test panel, the relevant standard or test method should be consulted, or contact AML for help and advice.

In a similar manner to the 180-degree test panels, these are often float glass or stainless steel. The properties, method, or specimen preparation are closely controlled to ensure repeatability and reproducibility.

ASTM-D6252 – Standard Test Method for Peel Adhesion of Pressure-Sensitive Label Stocks at a 90° Angle

ASTM-D3330 – Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

ASTM-B533 – Standard Test Method for Peel Strength of Metal Electroplated Plastics

ASTM-B571-97 – Standard Practice for Qualitative Adhesion Testing of Metallic Coatings

ASTM-D816 – Standard Test Methods for Rubber Cements

ASTM-D429 – Standard Test Methods for Rubber Property—Adhesion to Rigid Substrates

ASTM-D6862 – Standard Test Method for 90 Degree Peel Resistance of Adhesives

BS EN-1939 – Self-adhesive tapes. Determination of peel adhesion properties

BS EN-2243-3 – Aerospace series. Non-metallic materials. Structural adhesives. Test method. Peeling test metal-honeycomb core

BS EN-28510-1 – Adhesives. Peel test for a flexible-bonded-to-rigid test specimen assembly. 90° peel

ISO-8510-1 – Adhesives - Peel test for a flexible-bonded-to-rigid test specimen assembly - Part 1: 90-degree peel

SAE-J 1553 – Cross Peel Test for Automotive-Type Adhesives for Fiber reinforced plastic (FRP) Bonding

FINAT-FTM2 – Peel adhesion (90°) at 300 mm per minute

IPC-TM-650 – IPC-TM-650 Test Methods Manual

Afera-5001 – Self Adhesive Tapes - Measurement of Peel Adhesion from Stainless Steel or from its own Backing

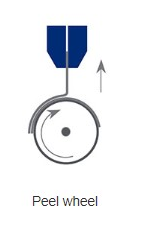

The climbing drum peel test (often referred to as the German wheel peel test) is a less common test, but can also be used where a flexible material and rigid substrate requires testing.

Diagram of a peel wheel (climbing drum peel test).

Diagram of a peel wheel (climbing drum peel test).

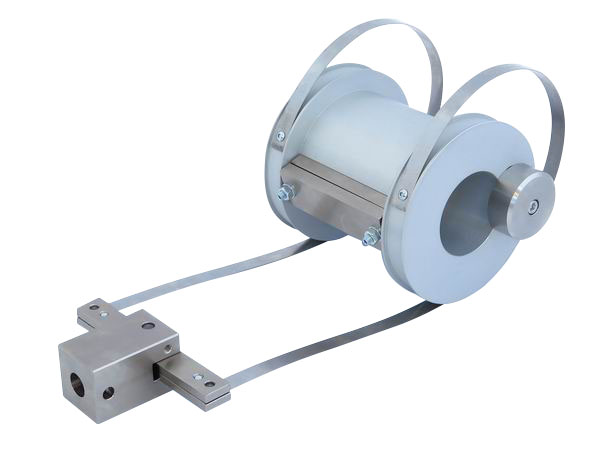

In the image below there is a German Peel Wheel. Peel wheel tests are easy to perform and less fiddly to set up compared to a 90-degree peel table test.

Metal peel wheel fixture, typically used in climbing drum peel tests or adhesive testing.

Metal peel wheel fixture, typically used in climbing drum peel tests or adhesive testing.

The image below shows the type of climbing drum peel test used on composites honeycomb panels typically to the requirements of ASTM D1781, EN 2243-3 or DIN 53295.

Climbing drum peel test fixture, a mechanical device used to measure the adhesive strength of bonded materials.

Climbing drum peel test fixture, a mechanical device used to measure the adhesive strength of bonded materials.

DIN 53357-B

ISO 6133

ASTM-D1781 – Standard Test Method for Climbing Drum Peel for Adhesives

ASTM-D1995 – Standard Test Methods for Multi-Modal Strength Testing of Adhesives

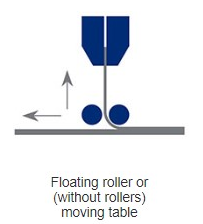

Diagram of a floating roller peel test setup, specifically configured for a 115-degree peel angle.

Diagram of a floating roller peel test setup, specifically configured for a 115-degree peel angle.

There are many types of peel fixtures for the Floating Roller Peel Test. It is similar to the other tests described so far, as it is suitable for a rigid or semi-rigid substrate and flexible material.

The rollers are generally set at 90 or 115 degrees, but we have options for adjustable angle fixtures. These rollers are set a small distance apart to allow the thin and flexible material to pass through them. This is attached to another grip attached to the tensile tester, maintaining the required test angle.

90-degree peel test machine, used for testing the adhesion strength of materials such as tapes, films, adhesives, and laminates.

[gallery link="file" columns="2" size="medium" ids="96241,96242"]

ASTM-D3167 – Standard Test Method for Floating Roller Peel Resistance of Adhesives

BS EN-1372 – Adhesives. Test method for adhesives for floor and wall coverings. Peel test

BS EN-1464 – Adhesives. Determination of peel resistance of high-strength adhesive bonds. Floating roller method

BS EN-2243-2 – Aerospace series. Non-metallic materials. Structural adhesives. Test method. Peel metal-metal

DIN EN-1464 – Testing of adhesives for metals and adhesively bonded metal joints; floating roller peel test

ISO-10373-1 – Identification cards - Test methods - Part 1: General characteristics

ISO-14676 – Adhesives - Evaluation of the effectiveness of surface treatment techniques for aluminium - Wet-peel test by the floating-roller method

ISO-4578 – Adhesives - Determination of peel resistance of high-strength adhesive bonds - Floating-roller method

The loop tack test is the measure of the “initial grab” or “tack” of pressure-sensitive tapes or adhesives.

Loop tack adhesive test setup, which measures the tack or initial stickiness of adhesive materials.

A loop of material is brought into contact with the standard material, usually glass or stainless steel. The size of the loop and standard material size and specification along with the speed of the test are set down in the relevant standard. The test measures the force required to pull the tape or adhesive away from the test panel.

FINAT-FTM 9 – Loop tack measurement

ASTM-D6195 – Standard Test Methods for Loop Tack

BS EN-1719 – Adhesives for paper and board, packaging and disposable sanitary products. Tack measurement for pressure-sensitive adhesives. Determination of loop tack

PSTC-16 – Loop tack

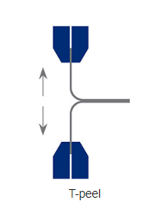

T Peel tests are usually performed when both the adhesive or tape has similar flexibility to the substrate. Both substrate & adhesive must be flexible to allow bending through 90 degrees without breaking. In the T peel test, the tails are unsupported so that the entire load is applied to the bond.

Diagram of a T-peel test setup, a common method for measuring the adhesive strength between two flexible materials.

Diagram of a T-peel test setup, a common method for measuring the adhesive strength between two flexible materials.

Of all the peel test methods this one tends to provide the lowest force values. When testing very low peel force materials the weight of the tails will affect the results obtained. This can also add significant variation to the results.

If testing an adhesive or tape to a more rigid substrate then the 90 or 180-degree methods are more suitable.

ASTM-D1876 – Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)

ASTM-D1995 – Standard Test Methods for Multi-Modal Strength Testing of Adhesives (Contact Adhesives)

ASTM-D2918 – Standard Test Method for Durability Assessment of Adhesive Joints Stressed in Peel

ASTM-D413 – Standard Test Methods for Rubber Property—Adhesion to Flexible Substrate

ASTM-D5170 – Standard Test Method for Peel Strength ('T' Method) of Hook and Loop Touch Fasteners

ASTM-D6496 – Standard Test Method for Determining Average Bonding Peel Strength Between the Top and Bottom Layers of Needle-Punched Geosynthetic Clay Liners

ASTM-F2256 – Standard Test Method for Strength Properties of Tissue Adhesives in T-Peel by Tension Loading

ASTM-F88 – Standard Test Method for Seal Strength of Flexible Barrier Materials

BS EN-12242 – Touch and close fasteners. Determination of peel strength

BS EN-1895 – Adhesives for paper and board, packaging and disposable sanitary products - 180°-'T' peel test for a flexible-to-flexible assembly

BS EN-868-5 – Packaging materials and systems for medical devices which are to be sterilized. Heat and self-sealable pouches and reels of paper and plastic film construction. Requirements and test methods

ISO-11339 – Adhesives - T-peel test for flexible-to-flexible bonded assemblies

ISO-20344 – Personal protective equipment - Test methods for footwear

After selection of the correct type of peel test, the next most important part of the test is the sample preparation. Each of the standards listed in this guide will have an exact method of sample preparation.

As well as determining the correct test and method for your needs, AML Instruments are on hand to help with this too. We can also provide a quotation for the test instrument required for your particular test, or professional advice on how to perform the test.

We do not source solutions from a single manufacturer, so can offer you the very best equipment to match your requirements exactly. As well as standard solutions, we can design and manufacture bespoke test equipment. Contact us today with your adhesive and tape testing challenge — advice and consultancy is always available to help you make the right decisions and correctly specify the methods and equipment needed.

Important: Before attempting any adhesive tests you should study the relevant standard to ensure the test is performed exactly as stated, any deviation from the published method will mean significant errors in the data collected from the test.

Interested in more practical formulation guidance on peel strength? Check out this guide from SpecialChem which focuses specifically on formulation methods to improve the peel strength in adhesives.

Let us help you