We’re here to help

Let us help you

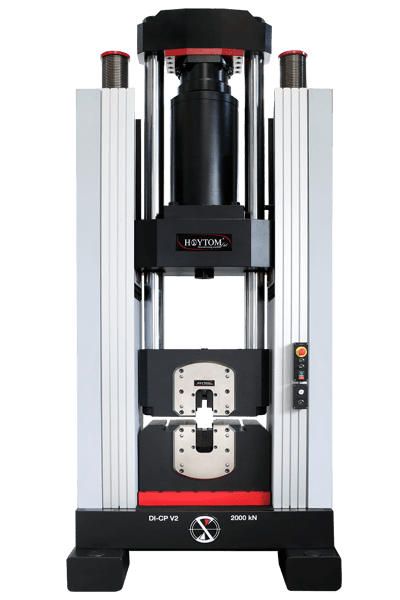

1500 & 2000kN Servo Hydraulic Universal Testing Machines DI-CP-V2 HOYTOM® PRO Series

Manufactured by Hoytom

Servo Hydraulic Universal Testing Machines DI-CP-V2 HOYTOM® PRO Series

The DI-CP-V2 is part of the Hoytom Pro Series of Servo Hydraulic Universal Testing Machines from Hoytom in Spain.

Capacities 1500 & 2000kN.

Adjustable cross head position via electromechanical ball screw system. Making this a very versatile machine for just about any type of testing.

Dual testing area, tensile in the lower area and comes equipped with hydraulic wedge grips. The upper area is used for bend and compresive tests.

Hoytom HoyWin® powerful yet initiative software & PC supplied with every machine.

Is this not the Universal Testing Machine / Tensile Tester you were looking for? We have a huge range of Materials Testing Machines Available

| Capacity kN | 1500 – 2000 kN | |

|---|---|---|

| Piston speed mm | Forward Backward |

150 150 |

| Approach speed *1 mm | 100 | |

| Piston travelmm | 300 | |

| Separation between grips mm | 50 – 1350 | |

| Tensile horizontal space mm | 890 | |

| Maximum height mm | 4620 | |

| Dimensions mm | Width Depth Height |

1500 1100 3400 |

| Weight Kg | 6500 | |

| Power supply V | 380 – III | |

| Power w | 4000 | |

| Force transducer | |

|---|---|

| Machine accuracy (Class)*2 | 0.5 |

| Range | 0.4% – 100% FS |

| Resolution | 0.001% FS |

| Displacement transducer | |

|---|---|

| Type | Encode line |

| Resolution | < 0.01 mm |

| Precision | < 0.1% |

Let us help you