We’re here to help

Let us help you

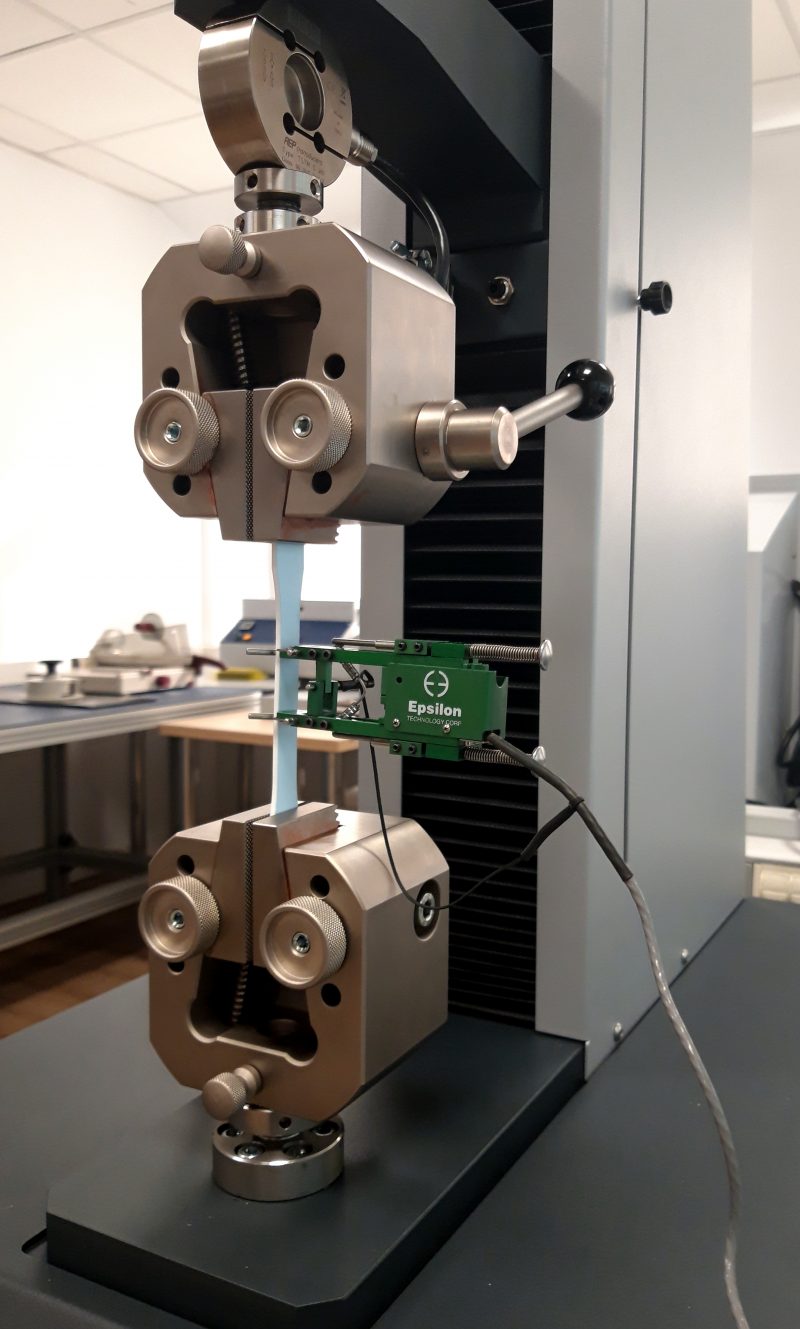

material is connected to the base of the Tensile Testing Machine. The Tensile Testing Machine is then used to pull the material apart at a controlled and speed appropriate for the material being tested and when following a ISO or ASTM standard to the speed set out in that particular standard. The term Tensile Testing Machine is widely used but actually the correct name these days for this type of materials testing equipment is a Universal Testing Machine because modern Tensile Testing Machines can be used to make many 100's of different tests not just tensile tests! A Tensile Testing Machine will also measure the position of the arm where the load cell is fitted this is utilised to calculate the strain or elongation of the material.

material is connected to the base of the Tensile Testing Machine. The Tensile Testing Machine is then used to pull the material apart at a controlled and speed appropriate for the material being tested and when following a ISO or ASTM standard to the speed set out in that particular standard. The term Tensile Testing Machine is widely used but actually the correct name these days for this type of materials testing equipment is a Universal Testing Machine because modern Tensile Testing Machines can be used to make many 100's of different tests not just tensile tests! A Tensile Testing Machine will also measure the position of the arm where the load cell is fitted this is utilised to calculate the strain or elongation of the material.

AML Instruments range of Tensile Testers can be configured and supplied with the correct fixtures and grips to enable them to perform a multitude of different tests and they can also test many different materials and substances.

AML Instruments range of Tensile Testers can be configured and supplied with the correct fixtures and grips to enable them to perform a multitude of different tests and they can also test many different materials and substances.

Polymers play a vital part in everyone’s life in the 21st century. Some of the uses include, packaging, automotive, healthcare, construction, aerospace and electronics.

There are many different tensile and compressive tests possible and even more standards available from different standards institutes around the world. Below is a list of the main standards used in industry. AML will of course help you select the best test and relevant standard for your testing needs.

Tensile BS 2782:3 methods 326A-326C

Tensile strength and elongation BS 2782:3, ASTM D638, ASTM D882, ISO 527-1,2,3, ISO 1798, ISO 1926, JIS K7127, JIS K7161, JIS K7162

Flexural: ASTM D790, ASTM D6272, JIS K7017, JIS K7171

Compression ASTM D695, ASTM D1621, ASTM D3846, ISO 844, ISO 604, JIS K7092, JIS K7181

Dynamic / Fatigue: ASTM F1614

Determination of the bearing strength of rigid plastics: ASTM E1012

Peel, Tear and Coefficient of Friction (CoF):ASTM D903, ASTM D1894, ISO 8067, BS ISO 8295, ISO 6383-1, ISO 11897, JIS K6854-2, JIS K7125, ISO 7886-1

Shear: ASTM D3163, ISO 8067

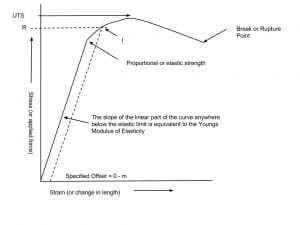

The tensile properties of polymers (plastics) that are regularly measured are tensile strength, yield strength, % elongation, elastic modulus and tensile energy absorbed.

Polymers play a vital part in everyone’s life in the 21st century. Some of the uses include, packaging, automotive, healthcare, construction, aerospace and electronics.

There are many different tensile and compressive tests possible and even more standards available from different standards institutes around the world. Below is a list of the main standards used in industry. AML will of course help you select the best test and relevant standard for your testing needs.

Tensile BS 2782:3 methods 326A-326C

Tensile strength and elongation BS 2782:3, ASTM D638, ASTM D882, ISO 527-1,2,3, ISO 1798, ISO 1926, JIS K7127, JIS K7161, JIS K7162

Flexural: ASTM D790, ASTM D6272, JIS K7017, JIS K7171

Compression ASTM D695, ASTM D1621, ASTM D3846, ISO 844, ISO 604, JIS K7092, JIS K7181

Dynamic / Fatigue: ASTM F1614

Determination of the bearing strength of rigid plastics: ASTM E1012

Peel, Tear and Coefficient of Friction (CoF):ASTM D903, ASTM D1894, ISO 8067, BS ISO 8295, ISO 6383-1, ISO 11897, JIS K6854-2, JIS K7125, ISO 7886-1

Shear: ASTM D3163, ISO 8067

The tensile properties of polymers (plastics) that are regularly measured are tensile strength, yield strength, % elongation, elastic modulus and tensile energy absorbed.

What is Tensile or Compressive Testing[/caption]

There are a huge range of standards that cover the tensile and compressive tests of metallic (metals) Below are a list of the most common ones.

What is Tensile or Compressive Testing[/caption]

There are a huge range of standards that cover the tensile and compressive tests of metallic (metals) Below are a list of the most common ones.

| Standard | Description |

| ASTM B598 | This standard covers the determination of the yield strength (0.01%, 0.02%, and 0.05% offset), at room temperature. It is intended for copper alloys in tempers commonly used for spring applications, and materials thicker than 0.010 in. (0.25 mm). |

| ASTM E209 | This standard covers the method, equipment, and specimens for compression tests on metallic materials. |

| ASTM E21 | This standard covers the method and equipment for the determination of tensile strength, yield strength, elongation, and reduction of area of metallic materials at elevated temperatures. |

| ASTM E238 | This standard covers the a pin-type bearing test of metallic materials to determine bearing yield strength and bearing strength. |

| ASTM E292 | This standard covers the determination of the time for rupture of notched specimens under conditions of constant load and temperature |

| ASTM E345 | This standard covers the tension testing of metallic foil at room temperature in thicknesses less than 0.006 in. (0.150 mm). |

| ASTM E8 | This standard covers the tension testing of metallic materials in any form at room temperature, in particular the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of area. |

| ASTM E9 | This standard covers the apparatus, specimens, and method for axial-load compression testing of metallic materials at room temperature. |

| BS 4A 4-1.2:1967 | This standard covers the specification for test pieces and test methods for metallic materials. Tensile tests. Tensile tests - elevated temperature. Metric units |

| BS 4A 4-1.3:1967 | This standard covers the specification for test pieces and test methods for metallic materials. Tensile tests. Uninterrupted creep and rupture tests. Metric units. |

| BS EN 10002-1:2001 | This standard covers the tensile testing of metallic materials. Method of test at ambient temperature. |

| BS EN 10002-5:1992 | This standard covers the tensile testing of metallic materials. Method of test at elevated temperatures. |

| BS EN 10319-1:2003 | This standard covers metallic materials. Tensile stress relaxation testing. method for testing machines. |

| BS EN 13523-7:2001 | This standard covers coil coated metals. Test methods. Resistance to cracking on bending (T-bend test). |

| BS EN 23312:1993, ISO 3312:1987 | This standard covers Sintered metal materials and hard metals. Determination of Young's modulus. |

| BS EN 23327:1993, ISO 3327:1982 | This standard covers hard metals. Determination of transverse rupture strength. |

| BS EN ISO 7438:2000 | This standard covers metallic materials. Bend test. |

| BS EN ISO 7500-1:2004 | This standard covers metallic materials. Verification of static uniaxial testing machines. Tension/compression testing machines. Verification and calibration of the force-measuring system |

| BS EN ISO 7622-2:1996 | This standard covers steel cord conveyor belts. Longitudinal traction test. Measurement of tensile strength. |

| BS EN ISO 8491:2004 | This standard covers metallic materials. Tube (in full section). Bend test. |

| BS EN ISO 8496:2004 | This standard covers metallic materials. Tube. Ring tensile test. |

| EN ISO 7438 | This standard covers metallic materials. Bend test. |

| ISO 10113 | This standard covers metallic materials. Sheet and strip. Determination of plastic strain ratio. |

| ISO 10447 | This standard covers resistance welding. Peel and chisel testing of resistance spot and projection welds. |

| ISO 1099 | This standard covers metallic materials. Fatigue testing. Axial force controlled method. |

| ISO 3327 | This standard covers hard metals. Determination of transverse rupture strength. |

Let us help you